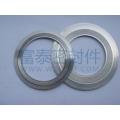

ASME B16.20 Stainless Steel 316L Graphite Spiral Wound Gasket

Basic Info

Model No.: 316L Graphite Spiral Wound Gasket

Product Description

Model NO.: 316L Graphite Spiral Wound Gasket

Standard: ASTM, AISI, GB, JIS, DIN, EN

Shape: Round

Surface Treatment: Bright

Trademark: C&N

Specification: customizable

Type: Gasket

Certification: ISO, SGS, BV, RoHS, IBR, AISI, ASTM, GB, EN, DIN, JIS

Technique: Cold Rolled

Mtc: Mtc En10204 3.1 Will Be Provided to All Goods.

Transport Package: Sea Worthy

Origin: China

Quick Details

Place of Origin: China (Mainland)

Brand Name: C&N

Model Number: 316L Graphite Spiral Wound Gasket

Material: Stainless Steel

Shape: Ring Gasket

Standard or Nonstandard:Standard

RAW MATERIAL: 304/304L/316/316L

FILLING: Graphite

THICKNESS: 3-4.5MM

Packaging & DeliveryPackaging Details:Delivery Detail:

| Wooden case or under customer's request |

| 7-45 days |

PRODUCT INTRODUCTION

ASME B16.20 Stainless Steel 316L Graphite Spiral Wound Gasket

Material: Stainless Steel 316L

FILLING: Graphite

Size: 1 inch - 120 inch

The Stainless Steel Spiral Wound Gasket adopts high-quality SUS304 or SUS316

("V" or "W"shape) metal strips, other alloy materials and some flexible materials like graphite,

asbestos, PTE and non-asbestos, which are overlapped and wound spirally with each other.

The metal strips are fixed on the initial and terminal ends by means of spot welding.

The metal spirally-wound gasket has the best resilien ce among the semi-metal hermetic gaskets.

Its structural density can be made subject to different locking forces.

Also the internal and external steel rings can be used to control its maximum compaction.

It's not demanding for the surface precision of the flange sealing surface contacting the

spirally-wound gasket. It's especially applicable for such occasions as uneven load, slack joint,

periodical changes of temperature and pressure, impact or vibration.

It's an ideal static seal element for flange connection in valves, pumps, heat exchangers, towers, manholes,handholes and so on.

Technology

Structural material of metallic wrapping pad:

| Filling | Steel band | Inner ring | Outer ring |

| Asbestos wrapping | SUS 304 | Carbon steel | Carbon steel |

| Graphite wrapping | SUS 316 | SUS 304 | SUS 304 |

| Teflon wrapping | SUS 316L | SUS 316 | SUS 316 |

| SUS 316L | SUS 316L |

| Filling | Temperature(ºC) | Max operating pressure(kg/cm2) |

| Asbestos wrapping | -200~550 | 250 |

| Graphite wrapping | -150~450 | 100 |

| Teflon wrapping | 240~260 | 100 |

| Flange type | Spiral wound gasket form |

| Flat face flange(F.F) | Wrapping pad with outer ring only |

| Wrapping pad with inner and outer rings | |

| Raised face flange(R.F) | Wrapping pad with outer ring only |

| Wrapping pad with inner and outer rings | |

| Male and female flange(M & F) | Basic wrapping pad |

| Wrapping pad with inner ring only | |

| Tongue and groove flange(T & F) | Basic wrapping pad |

| Wrapping pad with inner ring only | |

| Flat and groove flange(F & G) | Basic wrapping pad |

| Wrapping pad with inner ring only |

| Wrapping pad coefficient | m=2.5-4 |

| Wrapping pad service pressure | ≤25MPa |

| Wrapping pad service temperature | -196ºC-700ºC(Oxidizing medium no higher than 600ºC) |

| Wrapping pad minimum pretension specific pressure | y=68MPa |

Contact us if you need more details on 316L Graphite Spiral Wound Gasket. We are ready to answer your questions on packaging, logistics, certification or any other aspects about 316L Gasket、ASME B16.20 316L Gasket. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Spiral Wound Gasket

Premium Related Products

Other Products

Hot Products

ASME Explosive Cladding Steel Plates for Pressure Vessel, Explosion Bonded Clad Plates, Carbon+Duplex Explosion Cladding PlateJIS F 7309 Cast Iron 16k Globe ValveASTM B16.5 A105 Carbon Steel Reducing FlangeUns S32205, Duplex 2205 Stainless Steel Pipe Fitting Elbow Tee ReducerBrass Flanges, Brass Forged Flanges, Brass Forging FlangesS31803 S32750 S32760 Stud Bolts, S31803 S32750 S32760 Hex Bolts, DIN933 Bolts, D934 Nuts, Super Duplex Stainless Steel BoltsTitanium ASTM B363 Gr1, Gr2, Gr3, Gr7, Gr9, Gr11, Gr12 Elbow Pipe Fittings, Titanium Pipe Fitting (Elbow, U bend, Reducer, Tee, Stub End etc.)SABS 1123 Sans 1123 FlangeFlange Gasket, B16.20 Spiral Wound GasketB16.11 Pipe Fitting, Socket Weld Fittings, Thread Pipe Fitting, Scoket ElbowAluminum 6061 T6 Forged Welding Neck Flange, Plate Flange, Aluminum 6061 T6 FlangeJIS B2220 5k 10k 16k Flange, Slip on FlangeSpectacle Blind Flange, Figure 8 Flange, Stainless Steel Spectacle Blind Flange,DIN 2576 Pn10 Plate Flange, DIN2576 Pn10 Slip on FlangeForged Steel FlangeASTM A234 Wpb Elbow Butt Welding Pipe Fitting